Video

Evaluation of a NOx Transient Response Method for OBD of SCR Catalysts

2012-01-30

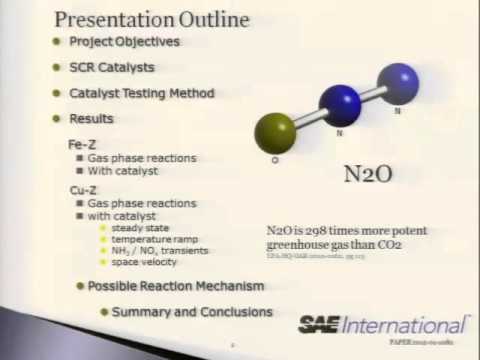

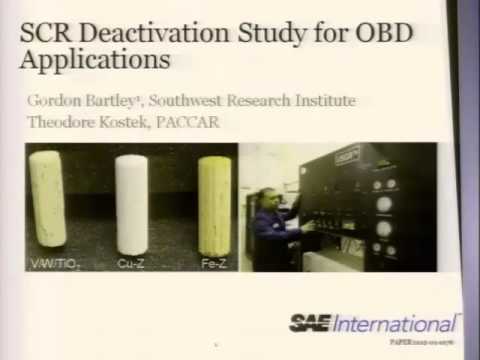

OBD requirements for aftertreatment system components require monitoring of the individual system components. One such component can be an NH3-SCR catalyst for NOx reduction. An OBD method that has been suggested is to generate positive or negative spikes in the inlet NH3 concentration, and monitor the outlet NOx transient response. A slow response indicates that the catalyst is maintaining its NH3 storage capacity, and therefore it is probably not degraded. A fast response indicates the catalyst has lost NH3 storage capacity, and may be degraded. The purpose of the work performed at Southwest Research Institute was to assess this approach for feasibility, effectiveness and practicality. The presentation will describe the work performed, results obtained, and implications for applying this method in test laboratory and real-world situations. Presenter Gordon J. Bartley, Southwest Research Institute